Cable Jointing

Cable jointing involves connecting lengths of power cables to ensure a continuous and reliable electrical path. Because this task is often on the critical path of project schedules, delays or mistakes can significantly impact overall timelines.

The cable jointing process includes several important stages, and due to the complexity and high safety requirements, should only be performed by trained and experienced professionals.

At SPIE Wind Connect, our team of specialists ensures each joint is completed to the highest standard—safely, efficiently, and in line with project demands—helping to reduce risks and avoid costly delays, no matter the size or complexity of your project.

Highly skilled cable jointers with proven field expertise

Certified to work on high-voltage networks up to 400kV

Advanced testing equipment for complete diagnostic-to-delivery solutions

Internal frameworks ensuring exceptional service quality

Testing and Termination

Testing and termination are critical stages in the successful delivery of high voltage infrastructure. These processes ensure that the power cables not only function correctly at the time of installation, but also continue to perform reliably throughout the lifespan of the system.

Our skilled cable jointers work with meticulous attention to detail, ensuring that every termination is executed flawlessly. By collaborating closely with cable manufacturers and asset owners, and by using the latest testing technologies, we deliver safe, high-quality installations.

This partnership-focused approach helps ensure on-time project delivery, long-term reliability of the electrical network, and a reduced risk of future faults”.

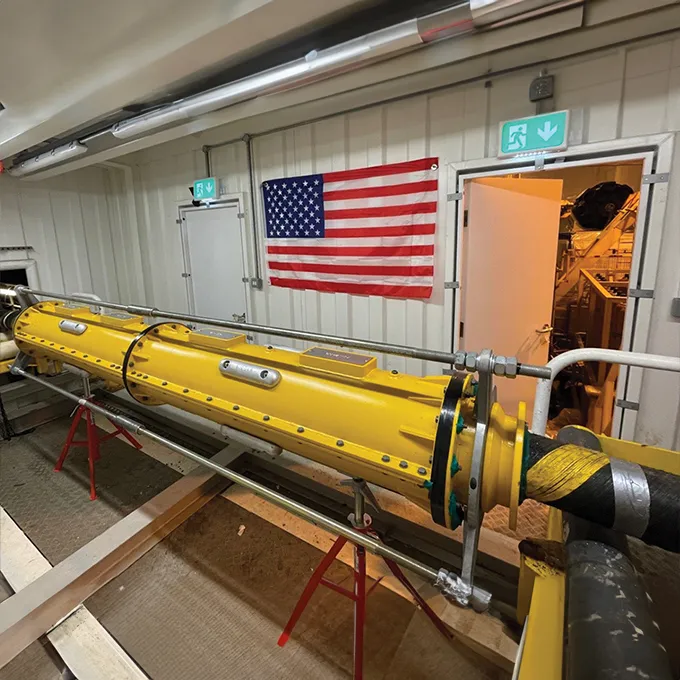

Splicing and Jointing

HV cable splicing and jointing is a critical element of offshore wind farm development. This process involves connecting segments of high-voltage subsea cables to create a continuous electrical circuit—enabling power generated by offshore turbines to be reliably transmitted to substations and ultimately to the onshore grid.

Due to the technical precision of this work, HV cable jointing offshore requires highly skilled engineers, specialist equipment, and full compliance with stringent industry standards.

SPIE Wind Connects experienced offshore cable teams are trained to deliver splicing operations to the highest level of quality and consistency—ensuring system reliability, minimising project risks, and supporting successful commissioning of offshore wind assets.